Mobile: +86 15890068607

Mobile: +86 15890068607

Email: nanbeiinstrument@nanbei-china.com

Email: nanbeiinstrument@nanbei-china.com

Mobile: +86 15890068607

Mobile: +86 15890068607

Email: nanbeiinstrument@nanbei-china.com

Email: nanbeiinstrument@nanbei-china.com

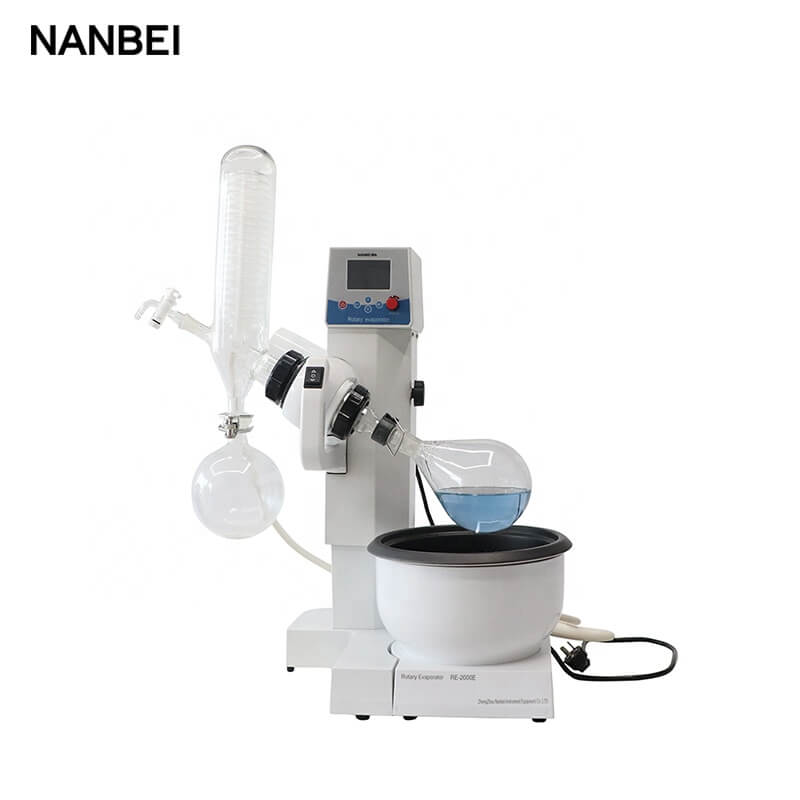

Rotary evaporator is a commonly used laboratory equipment, consisting of a motor, a distillation flask, a heating pot, a condenser tube, etc. It is mainly used for continuous distillation of volatile solvents under reduced pressure conditions, and is applied in chemistry, chemical industry, biomedicine and other fields. It is equipped with a double-layer high-efficiency condenser with fast condensation speed, which can be used with refrigeration cycle equipment to further accelerate the condensation efficiency, and has the function of preventing backflow of the evaporative condenser.

Advantages of laboratory rotary evaporator:

1. High evaporation efficiency and fast condensation speed. Under the action of centripetal force and frictional force, the experimental materials inside the rotating flask will form a thin film inside, which increases the evaporation area and greatly improves the evaporation efficiency.

2. The rotating flask is driven by the motor to rotate at a constant speed, and the generated force can effectively suppress the boiling of the material. High-efficiency double-layer condenser can be connected with cryogenic liquid circulation device and vacuum pump to ensure high recovery rate and rapid condensation.

Disadvantages of rotary vacuum evaporators:

The disadvantage of the rotary evaporator is that the boiling of some samples will lead to the loss of experimental materials. This problem can be solved by adjusting the working intensity of the vacuum pump or adding anti-boiling particles. When handling experimental materials that are particularly difficult to distill (including experimental materials that are prone to foaming), a special condenser can be configured for the rotary evaporator.

* HOT ARTICLE

Welcome to the official website of the Nanbei Group *