Mobile: +86 15890068607

Mobile: +86 15890068607

Email: nanbeiinstrument@nanbei-china.com

Email: nanbeiinstrument@nanbei-china.com

Mobile: +86 15890068607

Mobile: +86 15890068607

Email: nanbeiinstrument@nanbei-china.com

Email: nanbeiinstrument@nanbei-china.com

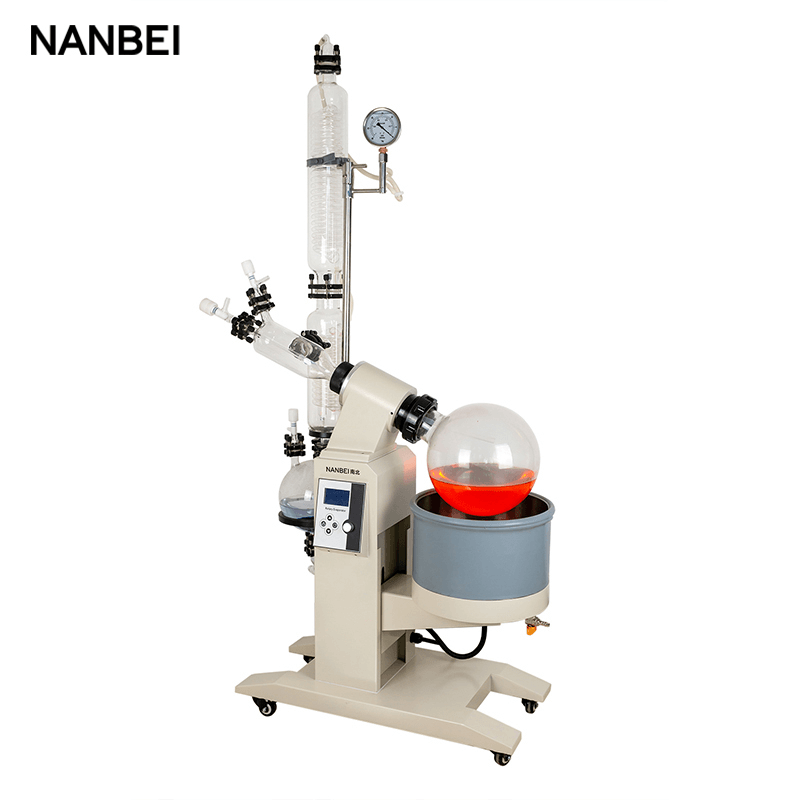

Rotary evaporator is an evaporation instrument widely used in laboratory, which is suitable for reflux operation, rapid evaporation of a large amount of solvent, concentration of trace components and reaction processes requiring stirring. It is widely applied in biological, medical, chemical and other fields. The rotary evaporator can be called a precision instrument, especially the flask and condenser tube that are all made of glass, we need to handle it with care.

Operating principle of vacuum rotary evaporator

Rotary evaporator is mainly used for concentration, crystallization, drying, separation and solvent recovery in pharmaceutical, chemical and biopharmaceutical industries. The principle is that under vacuum conditions, the rotary flask rotates at a constant speed by constant temperature heating, and the material forms a large area of film on the flask wall and evaporates. The solvent vapor is cooled by the glass condenser and recycled in the collection bottle, greatly improving the evaporation efficiency. It is especially suitable for the concentration and purification of biological products that are easy to decompose and denature at high temperature.

The rotary evaporator is sealed with PTFE and rubber, which can maintain high vacuum. The structure is reasonable and the materials used are particular. The mechanical structure is mainly made of stainless steel and aluminum alloy, and the glass parts are all made of high temperature resistant high borosilicate glass. The explosion-proof rotary evaporator adopts high efficiency condenser to ensure high recovery rate.

* HOT ARTICLE

Welcome to the official website of the Nanbei Group *