Mobile: +86 15890068607

Mobile: +86 15890068607

Email: nanbeiinstrument@nanbei-china.com

Email: nanbeiinstrument@nanbei-china.com

Mobile: +86 15890068607

Mobile: +86 15890068607

Email: nanbeiinstrument@nanbei-china.com

Email: nanbeiinstrument@nanbei-china.com

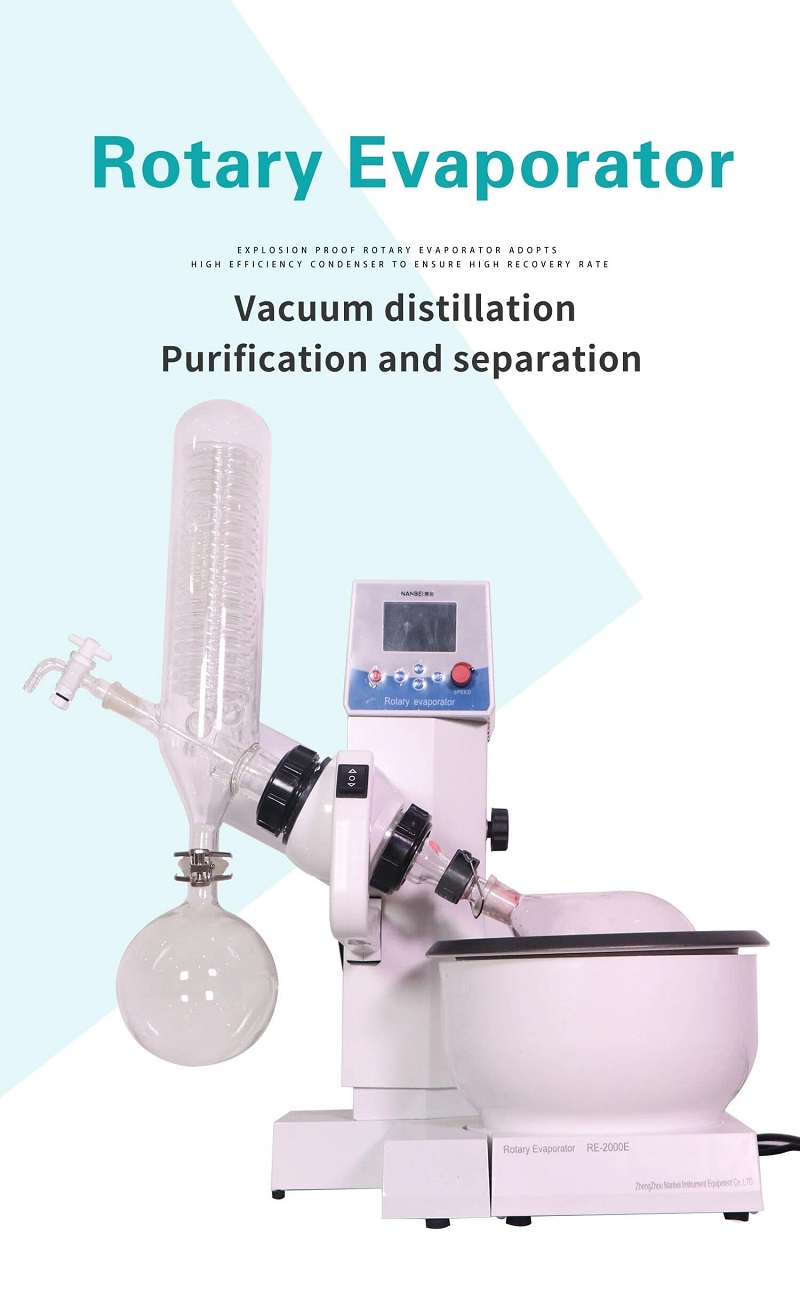

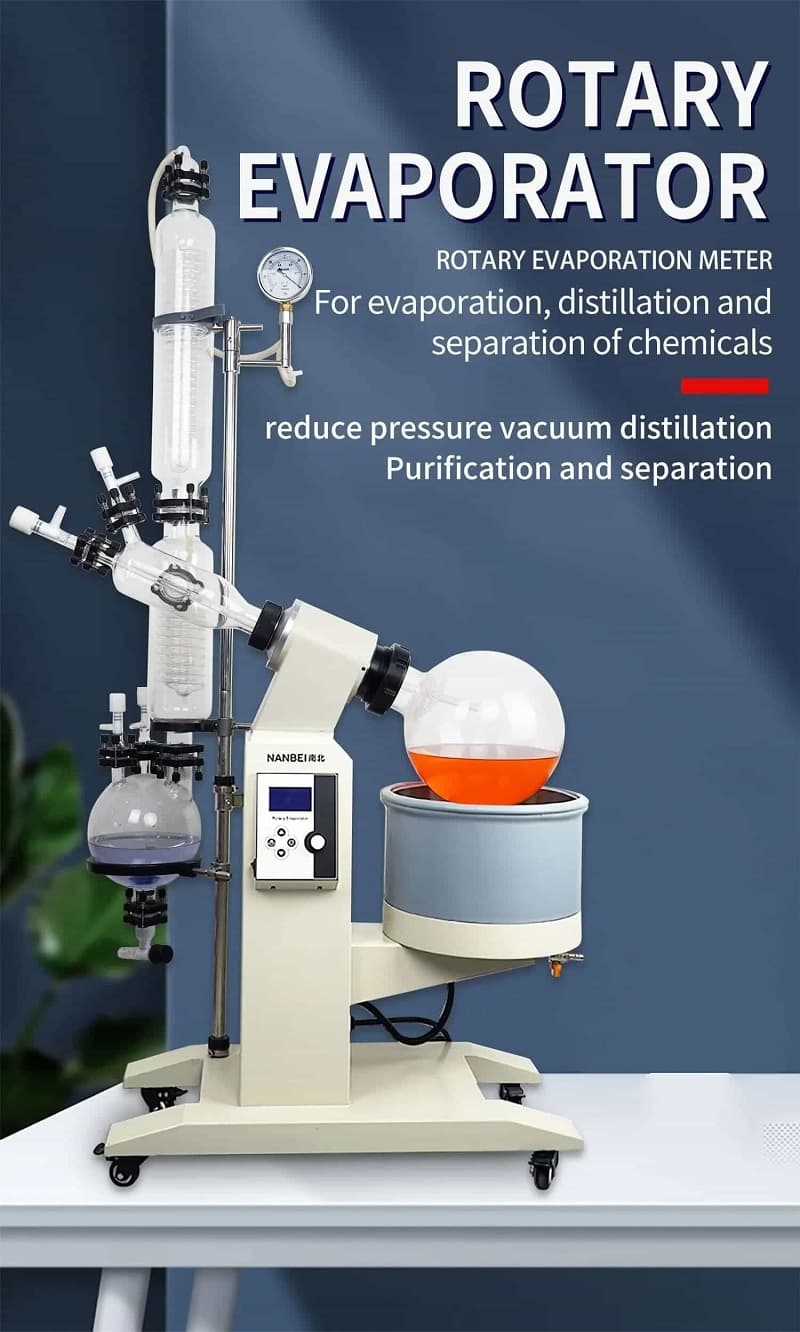

The rotary evaporator is a commonly used equipment in laboratories. It consists of a motor, a distillation flask, a heating pot, a condensation tube and other parts, which achieves rapid evaporation through heating and rotation. The evaporated material recovers the solvent through the condenser to achieve purification and separation. It is one of the indispensable equipment in the scientific research and production of medicine, chemical industry, biological products.

Four factors that affect the working efficiency of lab rotary evaporator:

1. Vacuum degree

The pumping capacity of the vacuum pump, the sealing and service life of the gasket, the fit of the glass grinding mouth, and the control of the vacuum degree.

2. Heating temperature

Heating capacity and stability of water/oil bath.

3. Cooling capacity of condensate

The cooling capacity of the cooling water circulation tank, the circulation power and head of the cooling water circulation tank.

4. Rotation ability

The stability of the rotating motor and the concentricity of the glass shaft and the main machine.

The vacuum rotary evaporator is mainly used for the continuous distillation of volatile solvents under reduced pressure. The basic principle is vacuum distillation. It is suitable for reflux operations, rapid evaporation of large amounts of solvents, concentration of trace components, and reaction processes that require stirring. In practical applications, in order to achieve good experimental results, it is necessary to pay attention to correct operation and proper maintenance.

* HOT ARTICLE

Welcome to the official website of the Nanbei Group *